We're almost finished with this merry month of May deconstructed screen printing. A long post but lots of photos. I'm sure some of you are thinking ... "oh my goodness, Diane, so many steps, so many rules, so much preparation! Why???" Because with DSP or breakdown printing, the possibilities are endless, the personal interpretations can reveal your artistic voice and there's a surprise in every screen (with apologies to Cracker Jacks). Not to mention, each original print can lead you to try beading, embroidery, or embellishment of all kinds.

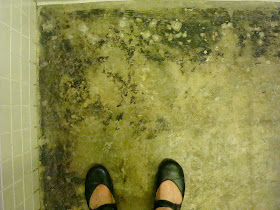

Where will you get inspiration? Anywhere there is texture, color and lines. In other words - everywhere! Is this mystery photo below a deconstructed screen print? Sure looks like one to me. Keep reading to learn where the photo was taken.

Prepare the fabric

Soak cotton fabric for at least 30 minutes in a solution of nine tablespoons to one cup (recipes vary) to one gallon of water. Wring out the soda water back into the bucket to reuse. Handwoven fabrics take longer to dry and seems like forever in 98% humidity. See the sky reflected in that puddle out there? That's my backyard and the waters have actually receded a lot. As long as you're looking, notice the last few gardenias on the bush on the left. Still a heavy perfume in the air.

Don't iron your soda-soaked fabrics - they are likely to get scorched - and I am not risking the same by using the dryer. Steady and slow. That's me... :(

Not really! I dug up some fabrics that had been stretched on a print board a couple of years ago and not used in a demo - so you know I have so many print boards that one can sit with unused fabric on it for years.

Prepare the screens

The dye on the screens has to be dry. I like to draw on the bottom side of the screen with thickened concentrated dye. At my house, it takes at least overnight for dye to dry on the screen. You can speed it up with a hair dryer but be careful you don't blow it around and spoil your intended design.

Stretch the dry soda-soaked fabric on print boards

I use two layers of corrugated cardboard, covered in batting and protected by clear vinyl tablecloth. All duct taped to the underside. Short T-pins work well, pressed well down and out of the way of the screen.

This is a loosely woven cotton shawl about 30 inches wide and a couple of yards long. I have it arranged on the board so that I can print a border on each end and the middle is folded up and protected against drips and splatters by a piece of cloth.

Pull the prints

I used clear print paste which is just the thickener and a plastic squeegee - an old credit card will work also.

The screen printed really well! There was some left over fushia (maybe?) and some olive green that I had applied a couple of days ago. The stripes magically aligned from one print to the other because I had been careful in planning it. Or it was just dumb luck You decide.

There was only enough dye on the screen for one border so I applied more dye to the back of the screen and have to wait while it dries to complete this project It will only be a border print and probably I will have lots of backstaining over the entire shawl which really will not disappoint me. A little more color will make it more interesting.

Batch the prints

While I am waiting for the added dye on the screen to dye, I have placed plastic over the first border so it can batch for at least 48 hours. Because the second border will have to batch that long, the first border will be batching twice as long but in this case, more is better. Batching is just letting the wet dye sit on the cloth long enough to make a strong bond.

Wash out excess dye

One last step in the process. Washing up. A sometimes discouraging step. You will lose some color. No home dye formulation can be 100% perfect. Printing lays down more dye than the fabric can chemically take up, so the excess has to be removed. If you have vast areas of white fabric that is presoaked in soda, you may get some staining there, so the better choice is to avoid wide open white areas. Cover your design with dye if you can.

First wash with cool water to remove the thickener and excess dye. When you are bored with this step and the rinse water is mostly clear, begin to wash in very hot water with Synthapol or blue Dawn dishwashing soap. The soap will help prevent the backstaining. The hot water will loosen up the rest of the unused dye. I usually get my electric kettle whistling with boiling water and pour into a bucket. Add hot water from your faucet to bring the temperature down to about 140 degrees F. Let your fabric soak with a little soap overnight.

Take a break, read your email, go for a walk. Washing out is not the fun part of this job. Wring out and do another hot soak and washout. If you still have color in the rinse water, keep doing the 140 degree F soak with soap. I usually finish up with a small hot load (adding water from the whistling kettle, too) in the washing machine - assuming all the fabric is in a similar colorway to avoid cross backstaining.

Here's my washed-out, still slightly damp deconstructed screen printing on the borders of a handwoven scarf from Dharma.

I was really pleased to find there was no backstaining in the center of the scarf. I must be getting better at this dyeing thing. :)

Here's that mystery photo from the corner of the ladies room at Art Supply on Main. I love that they pulled up the old flooring and didn't bother to paint or refinish. Or maybe they have by now, I'll have to drop in and check one of the these days. Judging by my stash of art supplies, I do not need to go shopping at an art supply store, but still, there could be something new to try ....

Hope you enjoyed this month of posts on deconstructed screen printing. Writing up the May posts here got me excited all over again about printing. Check out my blog for more current work and come back here for Fabric Collage with Cris Winters in June.

Diane

http://yarngoddess.wordpress.com

linking up with Nina Marie's Off the Wall Friday

A TECHNIQUE DRIVEN Blog dedicated to mastery of surface design techniques. First we dye, overdye, paint, stitch, resist, tie, fold, silk screen, stamp, thermofax, batik, bejewel, stretch, shrink, sprinkle, Smooch, fuse, slice, dice, AND then we set it on fire using a variety of heat tools.

This has been brilliant! I am glad for the info in the lead up posts, too, so we can see where we might take the techniques ourselves.

ReplyDeleteSandy in the UK

Thank you so much. I shall be back for a slower read and study when our weather is warm and dry enough to work outside!

ReplyDeleteThanks, Sandy & Elle, I really appreciate your enthusiasm and wish you good luck in your printing.

ReplyDeleteDiane

This has been a great month Diane. Thanks for all your insights.

ReplyDeleteThanks for the fab information and the entertainment, I really enjoyed your journey and I am inspired to have another go at decon printing

ReplyDeleteGreat information in these posts.

ReplyDeleteMaggi, Wendy, Beth,

ReplyDeleteThanks for your comments and support. It was fun to review my printing process and get started on new pieces.

Diane